Operation of PWM-driven motors - servo motors and variable frequency drives (VFD) - causes several problems in equipment, including damage to the motor’s bearings due to leakage current causing electrical discharge machining (EDM) and damage to motor’s insulation. PWM motors also are a major source of EMI in equipment. These motor drive systems use pulsed power to drive the motors. As we are aware, the sharp edges of the pulses inevitably include high frequency components which can couple or radiate as noise to other parts of your system and cause unreliability, communication/control problems and EMC compliance issues.

These pulses are an essential requirement for driving these motors so we have a problem!

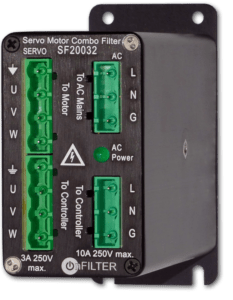

The Onfilter servo and VFD drive filters are located adjacent to the drive units and will significantly reduce the high frequency components of the drive signals, without affecting the system operation or performance. These patented SF-series filters substantially reduce high-frequency leakage currents in motors and in wiring, assisting in compliance with the requirements of IEC60034-17/-25. They also reduce interfering high-frequency noise within the tool resulting from operation of PWM-driven motors.

SF series filters greatly reduce high-frequency currents on equipment ground, as well as overall EMI in the tool, lowering risk of EOS and reducing errors in automated equipment and testers.

No Mechanical Fitting, No Wear, No Maintenance

OnFILTER' SF series filters have no mechanical coupling to the motors - all connections are electrical. Their cost of ownership is zero.

Click on the model that matches your requirements.

| Parameter | SF20031 | SF20032 | SF20101 | SF20201 |

| Max Drive Voltage | 250V | 250V | 250V | 250v |

| Max Drive current | 3A | 3A | 10A | 20A |

| Ground current reduction | 50…..100 times | 50…..100 times | 50…..100 times | 50…..100 times |

| AC mains voltage | 250V | |||

| AC mains current | 10A | |||

| AC noise reduction | >20dB | |||

| Dimensions (mm) | 47 x 102 x 150 | 47 x 102 x 150 | 47 x 102 x 150 | 40 x 164 x 184 |